You may be holding a laser-engraved product today, such as a pattern on a cell phone case or a beautifully textured ornament, and have no idea how it was made. Laser engraving is a process that uses a focused laser to alter (vaporize/carbonize/oxidize, etc.) a specified area of a material and leave a permanent, precise mark. Understanding it can help you choose the right method for personalization, prototyping, or small production runs.

In this article we will take you through an in-depth look at what laser engraving is, how it works, what types are available, the materials it is suitable for, and how you can utilize a laser engraver for revenue.

What is Laser Engraving?

Laser is the use of light to transmit energy, causing our materials to encounter high temperatures and thus vaporize. Laser engraving is a process of removing material from the surface of an object with a highly focused beam of light to create a permanent pattern. Think of it as a magnifying glass producing a focused beam of light in the sun, which vaporizes and etches the object through high temperatures onto the object.

The smaller the light is focused by a laser engraver, which can be as small as a few microns, the more precise and intricate the pattern it can engrave, which is why it is often used in design, industry, and artwork.

What's really exciting is the rise of the desktop laser engraver. Once used only in industrial factories, the technology has become compact, affordable, and simple enough for home studios, workshops, and small businesses as well. Of course, there are different types of laser engravers, such as fiber laser engravers and CO2 laser engravers, which we'll cover in more detail later.

How Does Laser Engraving Work?

The process of getting from a design on your computer to a finished product can be boiled down to a simple three-step workflow.

First, you start with a design. This design can be a logo, a photograph, or some text that you create. It can be a vector file (e.g. SVG), which is mainly used to achieve clear lines and cutting effects, or a raster file (e.g. JPG), which is used for detailed photo engraving. You can find them directly on some material platforms, such as vecteezy, pinterest, etc.

Next, you import that design into your laser engraver software. This is kind of like a print setup, but instead of choosing a paper type, you set the power and speed of the laser for the material you're using (like wood or leather). This software is the heart of the operation and tells the machine exactly what to do.

Finally, you press the “Start” button. The machine's controller translates your settings into precise movements and fires the laser to perfectly replicate your design on the material. The powerful energy of the laser beam instantly transforms the material:

- Evaporation or carbonization (for organic materials such as wood, leather, etc.).

- Melting or oxidizing or bursting (for inorganic materials such as metals, glass, etc.).

This is what creates marking depth and permanence.

A laser engraving machine is a powerful tool, but it needs clear instructions on how to operate it. The software is the bridge between your creativity and the physical machine. This also means that the learning curve is more about familiarizing yourself with digital operations than complex mechanical skills, which is good news for beginners.

Is Laser Engraving Permanent?

Absolutely. In fact, durability is just one of its biggest advantages.

Unlike ink that adheres to a surface or a sticker that might peel off, lasers physically alter the material itself by removing a layer of substance. Instead of a coating, it's etched into the object.

Your design will last as long as the material itself. It won't peel, fade or wash off. This is why it is one of the most popular processes available.

8 Advantages of Laser Engraving

1. High precision and detail

Laser engraving utilizes a focused laser beam to vaporize material with extreme precision. This allows for intricate patterns, fine text, barcodes, and even miniature markings that are not possible with traditional methods.

2. Lasting results

Unlike printing or etching, laser engraving physically alters the surface of the material. The markings will not fade, peel or wear off, which makes it ideal for use in industrial, commercial and personal applications.

3.Compatible with a wide range of materials

It works on metal, wood, glass, leather, stone and plastics, which makes it incredibly versatile for creative and industrial uses.

4. No contact or tool wear

Since the process is non-contact, there are no physical tools touching the surface , which also means no mechanical wear and no deformation. This also means that there is no mechanical wear and no deformation, and the maintenance costs of the machine are relatively low.

5. Fast and efficient

Laser engraving allows for fast, consistent and automated mass production. It is ideal for customized one-off projects and high volume production.

6.Environmentally Friendly

Laser engraving marks primarily through the laser light it produces, so there is no need for inks, chemicals or other consumables. It produces minimal waste and uses less energy than other marking methods.

7.Customizable and Flexible

You can easily switch between different designs through the software to personalize products, brands, serial numbers, etc. without the need for physical adjustments.

8. Professional finish

Laser engraving provides clear, sharp lines and high contrast, it provides a premium look for jewelry, signage, electronics and branded merchandise and can help you achieve more of your business goals.

How To Remove Laser Engraving From Metal?

With metals, this can be tricky and it's important to set reasonable expectations. Because laser engraving creates a permanent mark by removing material, it cannot simply be erased. Removal means that more material needs to be removed to level the surface.

For very minor surface scratches, mechanical polishing or sanding can sometimes be used. This involves treating the area with an abrasive of progressively finer grit to restore surface finish, but it is best suited to flat, simple surfaces.

For deeper engraving, the methods used will be more aggressive. Industrial techniques like abrasive blasting (sandblasting) are effective, but require special equipment and will definitely alter the surface texture of the metal.

For certain coated metals, such as anodized aluminum, chemicals can sometimes be used to remove the entire surface coating, but this can be a dangerous process that is best left to the professionals. The best strategy is always prevention—it is advisable to test on scrap before engraving the final product.

XLASERLAB E3

E3 Portable UV Laser Engraver

A compact yet powerful UV laser engraver designed for professionals and creators who demand precision and efficiency.

Learn MoreMaterials Suitable for Laser Engraving

Unlike other processes, laser engraving can be created using a wide variety of materials. For glass materials, you need to check if the machine supports it. There are some machines that only support colored glass and cannot support clear glass. Below are some of the common materials that can be engraved:

Laser Engraved Wood

Laser engraved wood is very popular. The laser brings out the natural grain of the wood, creating a beautiful, rustic contrasting effect that gives a warm and authentic feel. However, different woods react differently. Hardwoods like maple or cherry give crisp, clean results, while softwoods like pine sometimes have uneven results due to resin capsules.

Laser Engraving Leather

Laser engraving leather produces stunning, high-end results. The key is finding the balance between power and speed to get a rich, deep color imprint without burning the material.

Tip: Apply masking tape to the surface; it protects the surrounding leather from smoke stains and helps to sharpen the lines.

Glass Laser Engraving

When you laser engrave glass, the heat from the laser does not vaporize the material, but instead creates tiny cracks in the surface. This is what produces that elegant frosted look.

A popular trick among makers is to apply a thin layer of dishwashing liquid to the area being carved. This helps to dissipate heat and makes for a smoother, cleaner carving surface without creating sharp glass shards.

Laser Engraving Clear Acrylic

Clear acrylic is one of the most popular materials for laser engraving. The laser beam produces a smooth and crisp white engraving effect on the surface, making it ideal for signage, lighting, awards or displays.

It is important to note that cast acrylic and extruded acrylic react differently. Cast acrylic engraves a more delicate pattern with a more uniform effect; while extruded acrylic is prone to melt marks.

Laser Engraving Metal

Laser engraved metals achieve extremely high precision and contrast and are often used for industrial parts, tools, jewelry and custom gifts. Different metals behave slightly differently:

- Stainless steel: can be engraved directly for deep, long-lasting markings.

- Aluminum: requires coating or anodizing before engraving to get a clear pattern.

- Copper & Brass: Highly reflective, usually requires high power or the use of a fiber laser.

What Materials Cannot be Laser Engraved?

While laser engraving supports a wide variety of materials, there are some materials that cannot be used for engraving:

- PVC (polyvinyl chloride) - produces toxic chlorine gas when heated.

- Vinyl - similar to PVC, it releases harmful gases that are harmful to breathe.

- Teflon (PTFE) - heat resistant, but produces harmful fumes when exposed to laser light, making it unsuitable for engraving.

- Polycarbonate - burns, discolors or melts easily and cannot be engraved clearly, resulting in poor quality markings.

Types of Laser Engraving

The main types of laser engraving are fiber laser engraving machines, carbon dioxide laser engraving machines, and diode laser engraving machine. Each type has different advantages and is best suited for different materials.

Diode Laser Engraver

These are the most common and affordable desktop laser engravers for beginners and hobbyists. They are great for getting started and are effective on materials such as wood, leather, cardboard and dark acrylic. Their main limitations are that their light wavelengths penetrate right through transparent materials and they can only mark metals that have been treated with special coatings and can't really engrave bare metal.

CO2 Laser Engravers

co2 laser engraving machines are versatile in the field of crafting. They excel on materials such as wood, all types of acrylics (including clear), glass, leather and rubber. If you are seriously considering creating with these materials, co2 laser engravers are a big step up in power and performance. Their weaknesses are that they are not fine enough for engraving metals due to the large focal spot, as well as the higher maintenance costs of C02 lasers.

Fiber laser engravers

Fiber laser engravers are stronger when it comes to engraving metals. They can engrave deep and long-lasting patterns on materials such as stainless steel, aluminum, titanium, brass, and gold. They are also suitable for some hard plastics. But they cannot handle organic materials such as wood, glass or clear acrylic.

Laser Engraving Machine Price

The cost of machines can vary widely, but it's helpful to consider them in tiers based on performance.

For hobbyists and beginners, entry-level diode lasers typically cost around $200 to $2,000. These lasers are great for learning the tricks of trade, as well as for working with basic materials like wood and leather.

Powerful benchtop CO2 lasers and high-end diode systems in the prosumer and small business categories. These devices typically range in price from $2,000 to $8,000, with a much wider range of materials that can be processed and projects for which they are suitable.

For professional and industrial use, high-power carbon dioxide (CO₂) and fiber lasers range in price from $8,000 to well over $40,000. These machines are designed for high-volume production and specialized tasks such as deep metal engraving.

XLASERLAB E3

E3 Laser Engraver

A compact and high-precision UV laser engraver built for creators, designers, and professionals seeking cutting-edge engraving performance.

Coming Soon — Secure Your Spot Today

Pre-Order NowHow to Start a Laser Engraving Business?

Turning your passion into a business is an exciting step. The most successful businesses don't try to be all things to all people; they find a niche. Maybe you focus on fine wedding decorations, custom leather goods, or personalized pet collars. Find a community you love and create for them.

Before you start, create a simple business plan. Know your costs - machines, materials and your time. A common pricing formula is to add up the cost of materials, the cost of time and a little overhead. It's always a good idea to research what similar items sell for on platforms like Etsy to make sure your pricing is competitive.

Practice is everything! Familiarize yourself with your machines and materials before you sell your first item. Make samples, test your setup, and perfect your process. Your confidence will be reflected in the quality of your work.

You don't need a huge marketing budget to get started. Share your work on social media like Instagram or in local Facebook groups. People love to see the creative process! Attending local craft fairs is another great way to get direct feedback from customers and make your first sale.

How to Choose a Laser Engraving Machine

Choosing your first (or next) machine can be overwhelming, and as we said earlier when introducing types, it often leads to a tough choice—the creator's dilemma. Do you choose a CO2 laser and pass up bare metal processing? Or do you choose a fiber laser and miss out on wood and glass processing? For years, creators have had to make compromises.

But what if you didn't have to choose? What if there was a single machine that could process everything from glass and metal to wood and leather, and with better quality? That's where a new technology is revolutionizing tabletop creators.

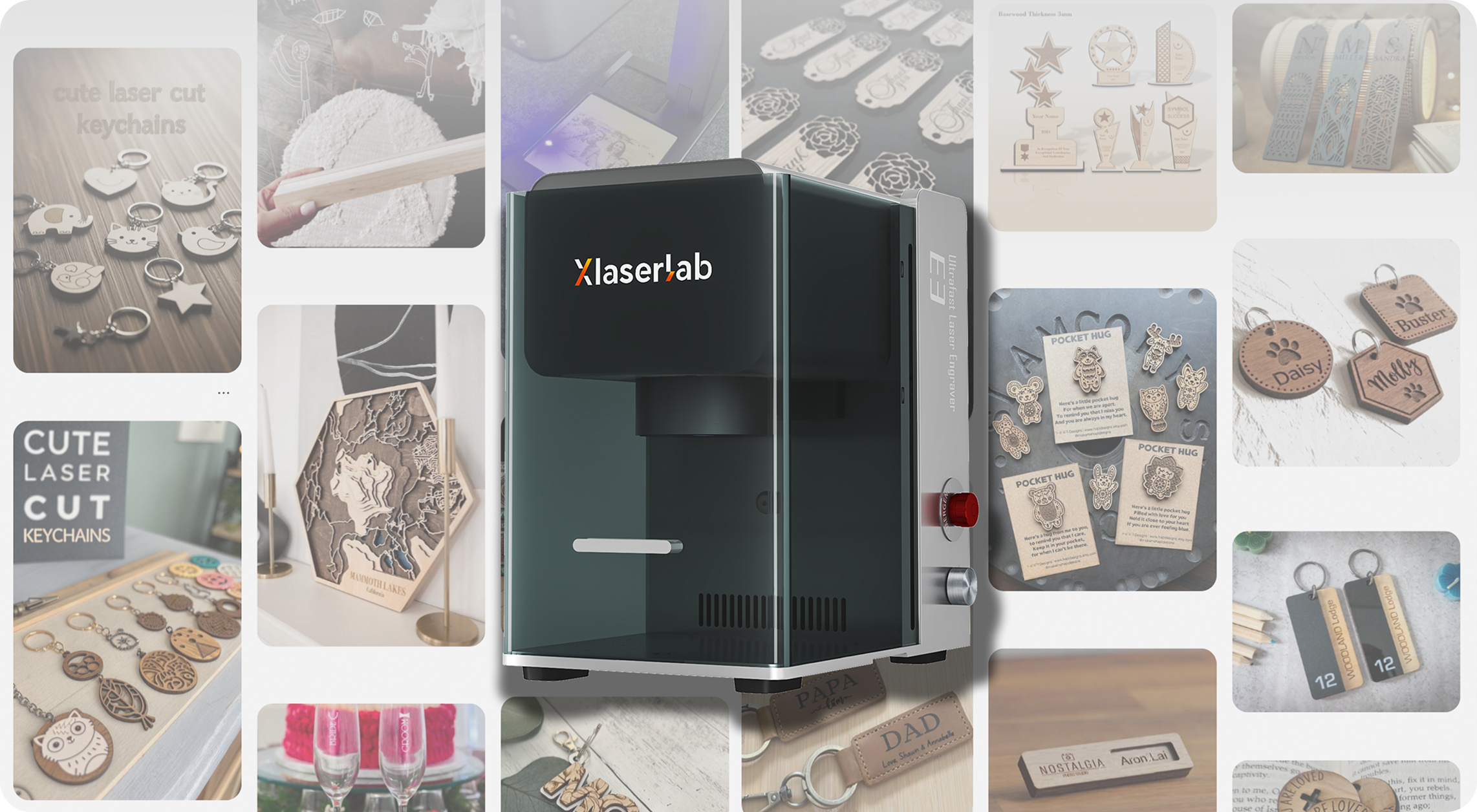

Focus: Xlaserlab E3 Laser Engraver

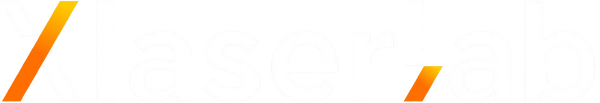

The Xlaserlab E3 laser engraver, a groundbreaking UV laser engraver, utilizes a “cold light” process. Instead of using intense heat that could scorch or melt the material, the xlaserlab e3 uses a 355nm UV laser that works at the molecular level. It directly breaks the chemical bonds of the material, allowing for extremely precise, burn-free results even on the most delicate materials.

There's a reason the E3 can do what no other single desktop device can. It engraves perfectly on clear glass and acrylic without any pre-treatment. It creates vibrant, long-lasting colors on stainless steel. And it still produces beautiful, detailed engravings on wood and leather. It's like having a diode, CO2 and fiber laser in one compact unit.

Users are often amazed at its ability to create over 200 different permanent colors on metals such as titanium and stainless steel. This is not a paint, but a microscopic alteration of the metal itself, creating an iridescent, high-value finish that feels amazing.

Another powerful feature is its ability to focus the laser inside a solid block of glass or crystal. This creates stunning 3D designs that look like they are suspended in mid-air.

Best of all, getting started is extremely easy.The E3 is equipped with an intelligent autofocus system and an HD camera that displays a live preview of the design directly on the material.For creators or entrepreneurs who refuse to be limited by tools, the xlaserlab e3 laser engraver represents a huge step forward.

Laser Engraving (FAQs)

What is the difference between laser engraving, etching and marking?

Engraving creates depth by physically removing material. Etching is technically a subset of engraving in that it creates raised markings by melting the surface, but the two terms are often used interchangeably. Marking is different - it uses a low-power laser to change the color of the material without removing much (if any) of the material.

Do I need special ventilation?

Yes, the engraving process produces fumes and exhaust. Some materials, such as leather or acrylic, can have a heavy odor, while others, such as PVC, are dangerously toxic. A good ventilation system or an exhaust gas extractor that can ventilate the fumes to the outside is essential for your health and safety.

What types of materials can be laser engraved?

Laser engraving works on a wide variety of materials, including wood, leather, glass, acrylic, and metals such as stainless steel, aluminum, copper, and brass. Each material reacts differently to the process, and some materials may require coatings or special settings for optimal results.

How do I choose the right laser engraver for my needs?

Choosing the right laser engraver depends on the materials you want to work with and your intended projects. Diode lasers are great for beginners and work well on wood and leather. CO2 lasers are versatile for crafting and can handle wood, acrylic, and glass. Fiber lasers are best for deep and lasting engravings on metals. Some advanced machines are designed to handle a broader range of materials.

Can laser engraving be removed from metal surfaces?

Removing laser engraving from metal is challenging because the process removes a layer of the material. Minor marks can sometimes be reduced with mechanical polishing or sanding, but deeper engravings may require abrasive blasting, which can alter the surface texture. For coated metals, chemical removal of the surface layer may be possible. Always test on scrap material first to avoid unwanted results.